Stainless Steel 2Quart Food Mill With 3 Discs HeavyDuty Kitchen

Basic Grain Mill Cleaning Every Brew Day. Aftering milling your grains and mashing in, take a few minutes to clean your grain mill. All it takes is a few simple tools: Compressed air; Brush (toothbrush or small paint brush) Lint-free cloth; Vacuum (Shop vac preferred) Follow these easy steps to ensure a clean and well-functioning grain mill.

Mill Clean Odplami Skoncentrowany płyn do odplamiania i czyszczenia

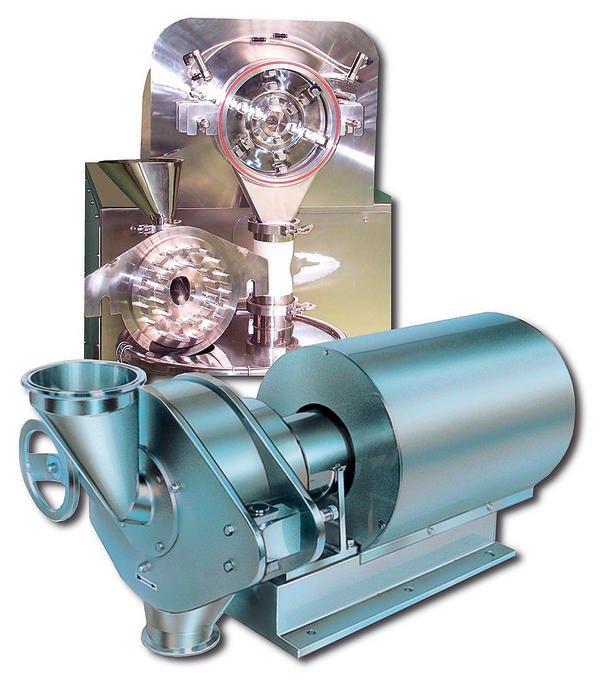

Essential specifications Ion optics Ultra-high-energy ion source with continuously and independently adjustable milling energy • 2-16 kV • Ion beam current range: 20 to 500 µA • Maximum sputter rate: >500 µm/hr Optional low-energy source

MILL SCALE REMOVAL MADE EASY WITH DUSTLESS BLASTING YouTube

CLEAN Mill Valley. Founded in 2012, involvement is by ordinary residents and participants from a number of Mill Valley organizations such as the Outdoor Art Club, Mill Valley Rotary, Mill Valley Chamber of Commerce, and Mill Valley StreamKeepers . Accomplishments Clean Mill Valley, in cooperation with the City of Mill Valley, helped evaluate.

MILL SCALE REMOVAL.. FOUND THE BEST STYLE ABRASIVE TO USE. YouTube

Unplug the grain mill if you have a motor-driven model. Wipe down the exterior with a clean, dry, lint-free cloth. Remove the hopper and the plates around your rollers using your screwdriver. Use the brush to clear any sticky debris from the rollers. Wipe all interior parts down with a second dry cloth.

Kemutec set to unveil new Easyclean Mill at POWTECH 2022 Kemutec

The ultra-high-energy ion gun features a maximum accelerating voltage of 16 kV to rapidly mill and polish sample surfaces. Ultra-fine surface polishing. The CleanMill System can be configured with an optional low-energy io n gun for final polishing of sample surfaces. Wide acceleration voltage

Clean Mill About Clean Mill

The ultra-high-energy ion source features a maximum accelerating voltage of 16 kV to rapidly mill and polish sample surfaces. Ultra-fine surface polishing. The CleanMill System can be configured with an optional low-energy ion gun for final polishing of sample surfaces. Wide acceleration voltage

Super Clean Mill

Joan Murray Honored at City Council Meeting. On January 8th, 2024, the Mill Valley City Council recognized our own Joan Murray, co-founder of Clean Mill Valley and long-time resident volunteer. Friends and family witnessed the City Council honor the extraordinary contributions of Joan to our community. She was presented with an official.

How to chemically remove Mill Scale hot rolled steel YouTube

To clean the body of the mill, we've used a drop of dish soap and water. To replace peppercorns, first unscrew the knob. Remove the head of the mill, and pour old peppercorns into a bowl. Empty.

Bezrat Food Mill Stainless Steel Kitchen Mill with 3 Discs for

Discover Clean Earth locations across the U.S. Comprehensive hazardous and non-hazardous waste disposal and recycling solutions.

Four Ways to Remove MILL SCALE YouTube

The Foley Manufacturing Company is the original creator of the food mill. Since the 1920s, it has been a go-to brand for housewares, but the food mill was especially innovative for its ability to efficiently sift flour. Its original purpose was to replace bulky flour sifters, the food mill is capable of much more.

Back to Basics How to Clean & Mill Grain into Flour! YouTube

Here's How To Clean The Mockmill In Between Uses…. Using Rice! Put a bowl in front of the Mockmill spout. Adjust the setting lever to position 10 (coarsest). Turn the mill on. Add 1/2 to 1 cup of white rice to the hopper. While it's milling, adjust from coarse to fine and back to coarse.

Mill Scale Should Welders Remove It? Welders Manual

Remove the head of the mill, and pour the old peppercorns into a bowl. You can further empty the reservoir by turning the mill upside down and rotating the grinder several times, and using a brush.

Mill Clean Mill Professional Kapsułki Piorące 10 Sztuk Baby Duo Caps

Cleaning an electric food mill works much the same as cleaning a manual food mill. You should carefully remove the grinding disk/sieve and then clean that with soap, water, and a brush, and then clean the bowl out. The important thing to keep in mind when cleaning an electric food mill is to not get any electrical components wet.

Super Clean Mill

Shot blasting is more time-consuming than using an angle grinder to remove the mill scale.Flame CleaningWith flame cleaning, you pass a hot oxyacetylene flame over the steel surface. It removes rust and mill scale, making the steel suitable for processing.Flame cleaning can remove paint, burrs, bad welds, defects, and surface imperfections.

Sell's Mill Free Stock Photo Public Domain Pictures

One of the most common ways to remove the mill scale from steel is chemical removal. It is a thorough method that also works very quickly and efficiently. With chemical cleaning, the mill scale layer is dissolved in acid, with acids like n hydrochloric acid, phosphoric acid or oxalic acid. A major disadvantage of dry cleaning is that it is.

Good results included

Join us for the launch of the Thermo Scientific CleanMill Broad Ion Beam System, a complete ion beam polishing solution that creates pristine surfaces on even the most air- and moisture-sensitive samples. We'll share how the CleanMill System can help R&D materials scientists, failure analysis engineers, and production quality control (QC) specialists quickly and effectively finalize a.